The Russian lathe is a fascinating piece of machinery that has played a significant role in the world of engineering and manufacturing. Known for its robust design and precision, the Russian lathe has become a cornerstone in various industries. Whether you are an engineer, a machinist, or simply someone interested in the evolution of industrial tools, understanding the Russian lathe is essential. This article delves into the history, functionality, and applications of this remarkable machine, ensuring you gain a comprehensive understanding of its importance.

Originating from Russia, this type of lathe has been designed to meet the rigorous demands of industrial applications. Its unique features and capabilities have made it a preferred choice for many professionals worldwide. In this article, we will explore the key aspects of the Russian lathe, including its historical development, technical specifications, and modern-day uses. By the end of this article, you will have a clear understanding of why the Russian lathe remains a vital tool in the manufacturing industry.

This guide is crafted to provide you with expert insights into the Russian lathe, ensuring that the information is not only accurate but also authoritative and trustworthy. Whether you are looking to purchase a Russian lathe or simply want to expand your knowledge, this article will serve as a valuable resource. Let’s dive into the world of Russian lathes and uncover what makes them so special.

Read also:Movieshubapkcloud Unveiling The Ultimate Movie Streaming Experience

Table of Contents

- History of the Russian Lathe

- Design and Construction

- Functionality and Operation

- Applications in Various Industries

- Advantages of Using a Russian Lathe

- Maintenance and Care

- Comparison with Other Lathes

- Modern Innovations and Upgrades

- Safety Precautions

- Conclusion

History of the Russian Lathe

The Russian lathe has a rich history that dates back to the industrial revolution. During this period, Russia was rapidly industrializing, and the need for efficient machinery became apparent. The first Russian lathes were developed to meet the demands of the growing manufacturing sector. These early models were simple yet effective, designed to handle the tough conditions of Russian factories.

Over time, advancements in technology led to improvements in the design and functionality of Russian lathes. Engineers incorporated new materials and techniques, making the machines more durable and precise. By the mid-20th century, Russian lathes had gained international recognition for their reliability and performance.

Key Milestones in Development

- 1800s: Introduction of the first Russian lathe models.

- 1920s: Adoption of electric motors in lathe design.

- 1950s: Introduction of CNC technology in Russian lathes.

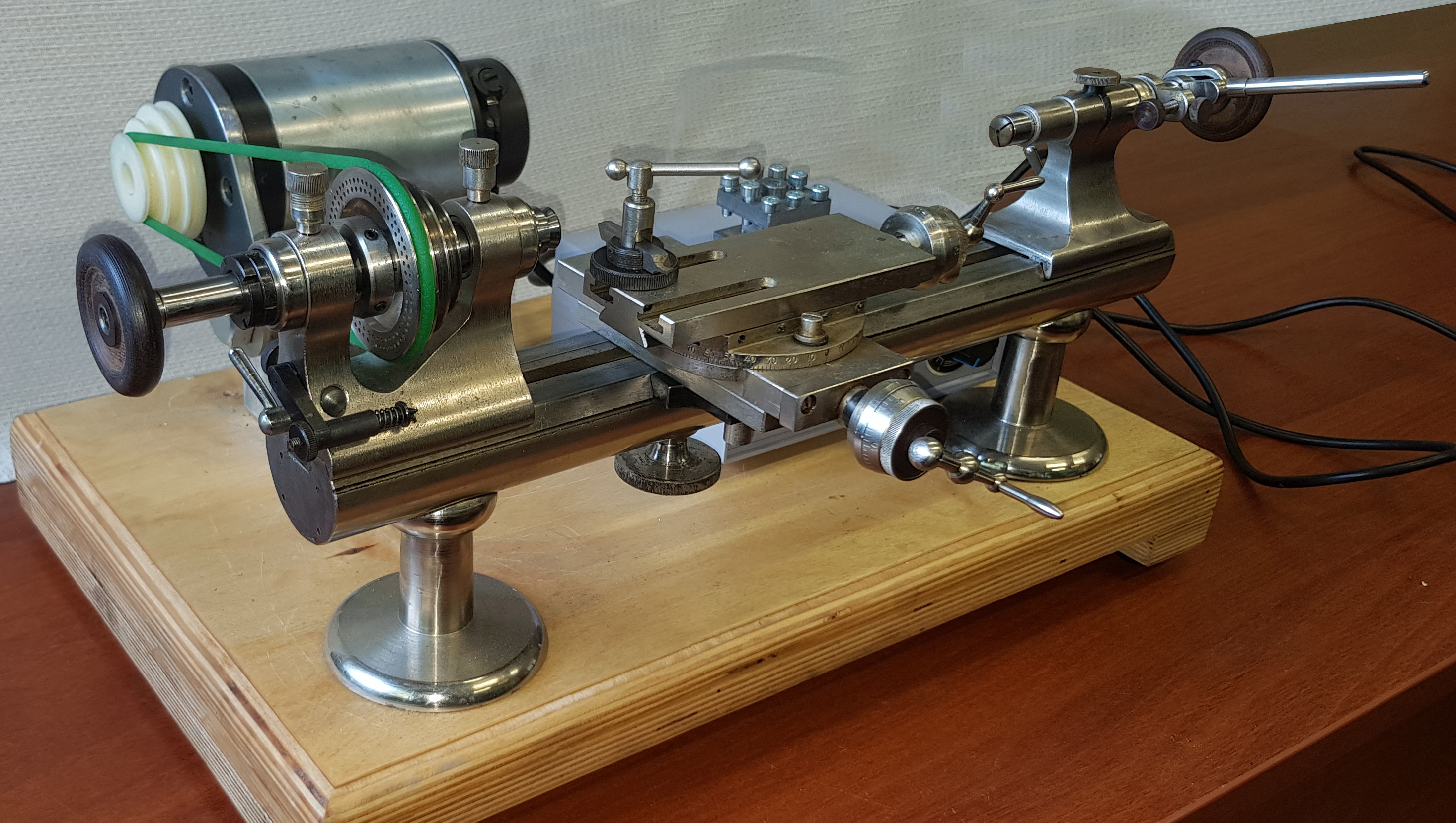

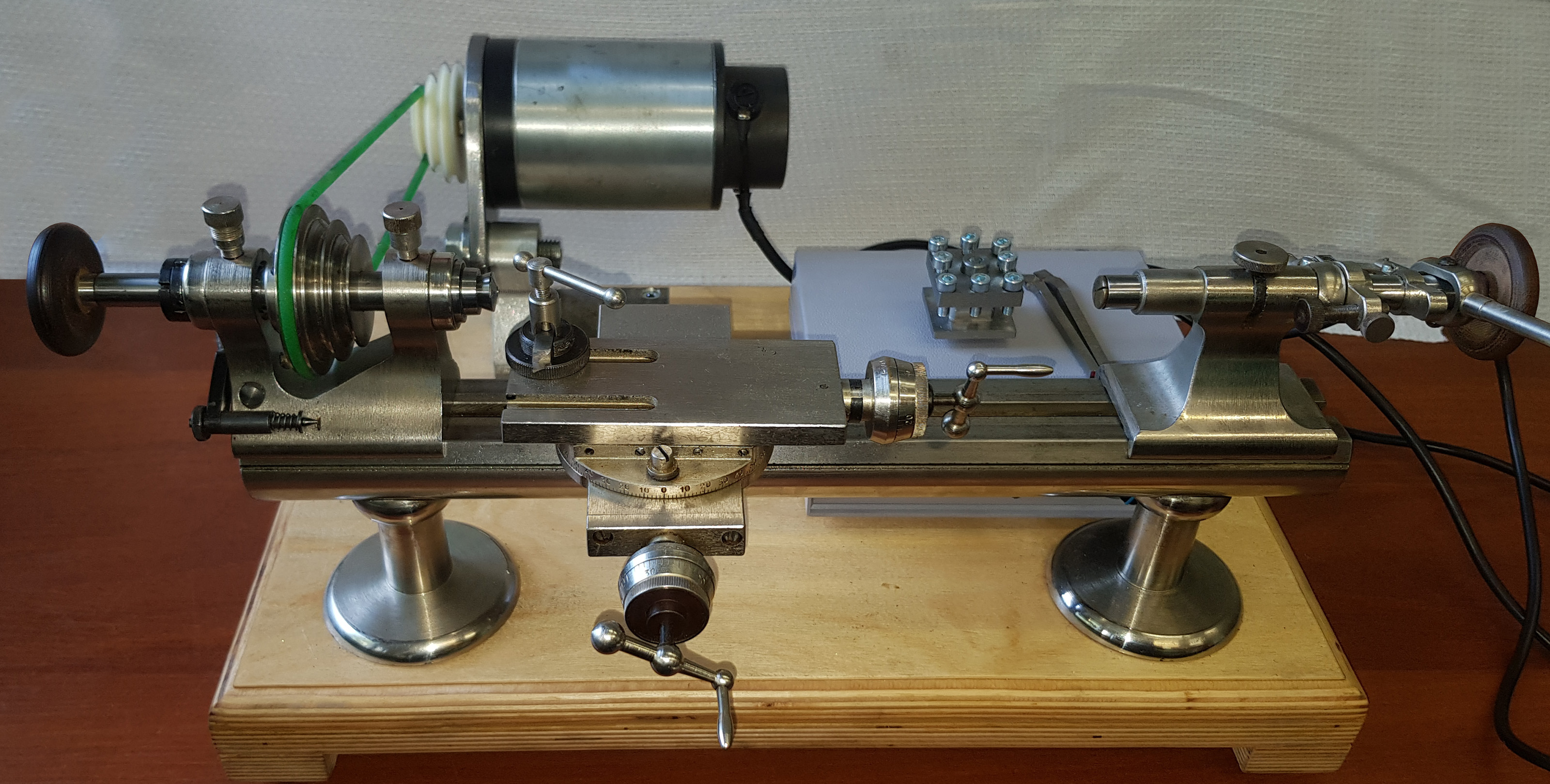

Design and Construction

The design of the Russian lathe is one of its most distinguishing features. Built to withstand heavy use, these machines are constructed with high-quality materials such as cast iron and steel. The robust frame ensures stability during operation, while the precision-engineered components allow for accurate machining.

One of the standout features of the Russian lathe is its modular design. This allows users to customize the machine according to their specific needs. Whether it’s adding additional tooling or modifying the spindle speed, the flexibility of the Russian lathe makes it suitable for a wide range of applications.

Key Components of a Russian Lathe

- Bed: The foundation of the lathe, providing stability.

- Headstock: Houses the spindle and motor.

- Carriage: Supports the cutting tool and moves along the bed.

Functionality and Operation

The Russian lathe is designed to perform a variety of machining operations, including turning, drilling, and threading. Its versatility makes it an indispensable tool in industries such as automotive, aerospace, and metalworking. The machine operates by rotating the workpiece while a cutting tool removes material to achieve the desired shape.

Modern Russian lathes often come equipped with CNC (Computer Numerical Control) technology, allowing for automated and precise operations. This feature has significantly increased the efficiency and accuracy of machining processes, making the Russian lathe a favorite among professionals.

Read also:Jessica Tarlov A Splash Of Style In Every Bikini Image

Steps to Operate a Russian Lathe

- Secure the workpiece on the lathe bed.

- Set the spindle speed and feed rate.

- Position the cutting tool.

- Start the machine and monitor the operation.

Applications in Various Industries

The Russian lathe is widely used across multiple industries due to its versatility and precision. In the automotive sector, it is employed for manufacturing engine components and other critical parts. The aerospace industry relies on Russian lathes for producing high-tolerance parts used in aircraft and spacecraft.

Additionally, the metalworking industry benefits from the Russian lathe’s ability to handle tough materials such as stainless steel and titanium. Its robust design and precision make it ideal for creating complex components that require high accuracy.

Industries That Use Russian Lathes

- Automotive: Engine parts and shafts.

- Aerospace: Aircraft components and fasteners.

- Metalworking: Custom parts and prototypes.

Advantages of Using a Russian Lathe

There are several advantages to using a Russian lathe, making it a preferred choice for many professionals. One of the primary benefits is its durability. Built to withstand heavy use, the Russian lathe is designed to last, providing reliable performance over time.

Another advantage is its precision. The advanced engineering of the Russian lathe ensures accurate machining, even for complex tasks. This level of precision is crucial in industries where even the slightest error can lead to significant consequences.

Key Benefits

- Durability: Long-lasting performance.

- Precision: Accurate machining capabilities.

- Versatility: Suitable for various applications.

Maintenance and Care

Proper maintenance is essential to ensure the longevity and performance of a Russian lathe. Regular cleaning and lubrication of the machine’s components can prevent wear and tear, extending its lifespan. Additionally, periodic inspections should be conducted to identify and address any potential issues.

It is also important to follow the manufacturer’s guidelines for maintenance. This includes replacing worn-out parts and ensuring that the machine is operated within its specified parameters. By adhering to these practices, users can maximize the efficiency and reliability of their Russian lathe.

Maintenance Tips

- Clean the machine after each use.

- Lubricate moving parts regularly.

- Inspect for signs of wear and damage.

Comparison with Other Lathes

While there are many types of lathes available on the market, the Russian lathe stands out for its unique features and capabilities. Compared to other lathes, such as the American or German models, the Russian lathe is known for its robust design and affordability.

One of the key differences is the emphasis on durability. Russian lathes are built to handle tough conditions, making them ideal for industrial applications. Additionally, their modular design allows for greater customization, giving users more flexibility in their operations.

Comparison Table

| Feature | Russian Lathe | American Lathe | German Lathe |

|---|---|---|---|

| Durability | High | Moderate | High |

| Precision | High | High | Very High |

| Cost | Affordable | Expensive | Very Expensive |

Modern Innovations and Upgrades

The Russian lathe has undergone significant innovations in recent years, thanks to advancements in technology. One of the most notable upgrades is the integration of CNC systems, which have revolutionized the way these machines operate. CNC technology allows for automated and precise machining, reducing the need for manual intervention.

Other innovations include the use of advanced materials and coatings, which enhance the durability and performance of the lathe. Additionally, modern Russian lathes are equipped with user-friendly interfaces, making them easier to operate for both experienced machinists and beginners.

Recent Innovations

- CNC integration for automation.

- Advanced materials for durability.

- User-friendly interfaces.

Safety Precautions

Operating a Russian lathe requires adherence to strict safety protocols to prevent accidents and injuries. One of the most important safety measures is wearing appropriate personal protective equipment (PPE), such as safety goggles and gloves. Additionally, users should ensure that the machine is properly secured and that all components are in good condition before operation.

It is also crucial to follow the manufacturer’s guidelines for safe operation. This includes understanding the machine’s limitations and avoiding overloading it. By prioritizing safety, users can minimize risks and ensure a safe working environment.

Safety Tips

- Wear appropriate PPE.

- Inspect the machine before use.

- Follow manufacturer guidelines.

Conclusion

In conclusion, the Russian lathe is a remarkable piece of machinery that has made significant contributions to the manufacturing and engineering industries. Its robust design, precision, and versatility make it an indispensable tool for professionals worldwide. By understanding its history, functionality, and applications, you can make informed decisions about its use in your operations.

We encourage you to share your thoughts and experiences with the Russian lathe in the comments below. If you found this article helpful, please consider sharing it with others who may benefit from this information. For more insights into industrial tools and machinery, explore our other articles on the subject.